Infrastructure

has built a solid foundation with a team of skilled employees and robust infrastructure, positioning the company to remain competitive”

has built a solid foundation with a team of skilled employees and robust infrastructure, positioning the company to remain competitive”

SPINNING

SPINNING

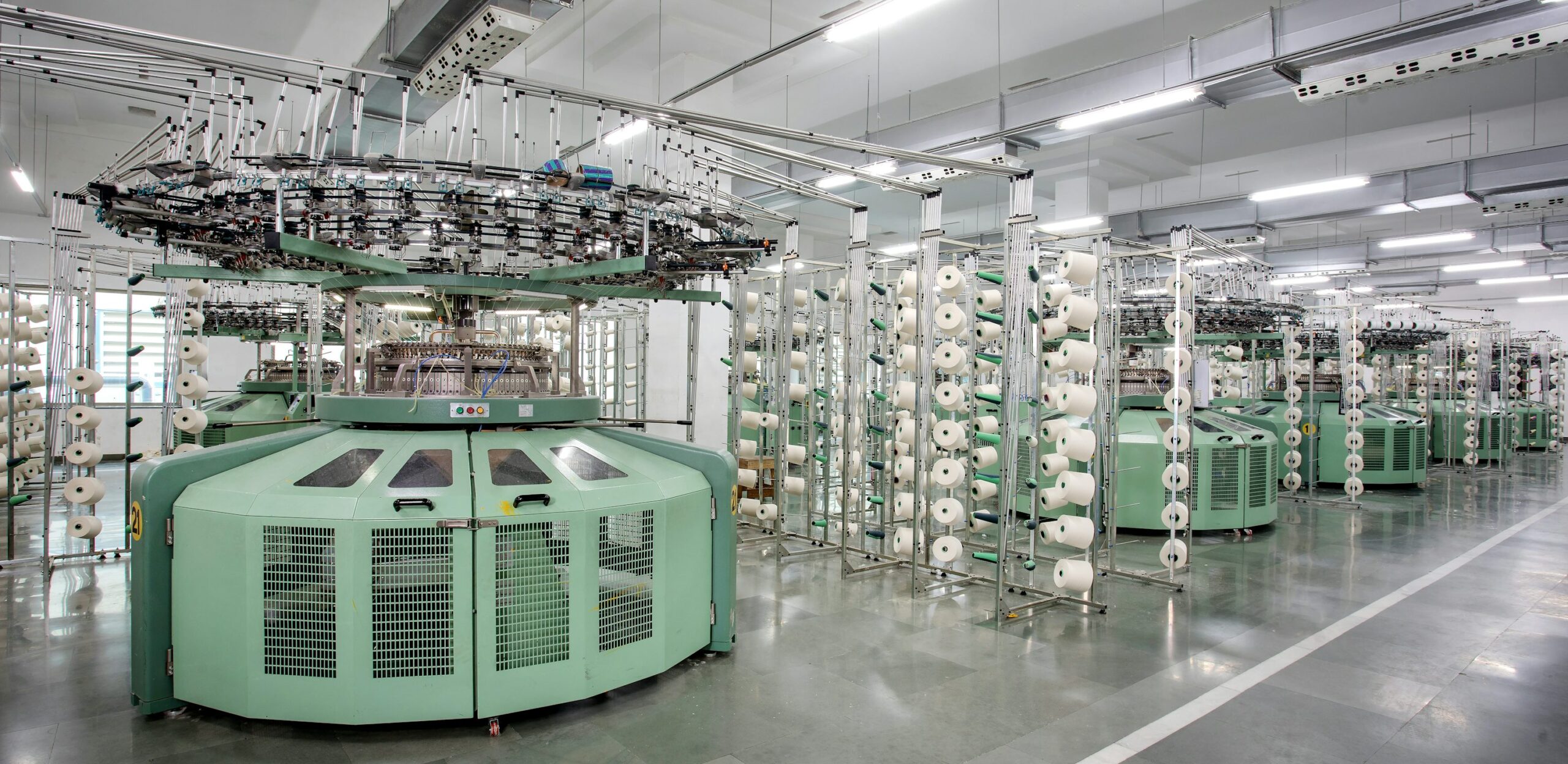

KNITTING

KNITTING

DYEING

DYEING

EMBROIDERY

EMBROIIDERY

SAMPLING DEPARTMENT

We have a dedicated sampling department focused on continuous innovation and staying attuned to global fashion trends in international markets. The team closely monitors current styles and utilizes the latest Computer-Aided Design (CAD) applications to swiftly bring ideas to life. The sampling department ensures alignment with these trends while forecasting colors, textures, styles, and designs for garments.

Sewing

The garments are produced using advanced, state-of-the-art technology in our in-house production unit. Our extensive range of machinery includes JUKI, BROTHER, and PEGASUS. Our production unit is supported by 120 sewing machines.

Printing

Our printing division is equipped with 12 chest printing machines, 12 fusing machines, 1 curing machine, and 4 manual printing tables to meet all our printing needs. All garments undergo a silicone softening wash and are made odour-free through the curing process.

Factory Premises

We typically handle orders with a lead time of 60 to 90 days, depending on the style and customer requirements. However, we are now focusing on delivering within 30 days for regular and basic products, similar to your local supplier.

We are equipped to handle minimum order volumes of 6,000 pieces per color. For larger quantities, the pricing will be more cost-effective, as per our standard pricing strategy.